19

2021

-

05

Magnesium aluminate spinel manufacturers take you to fully understand magnesium aluminate spinel

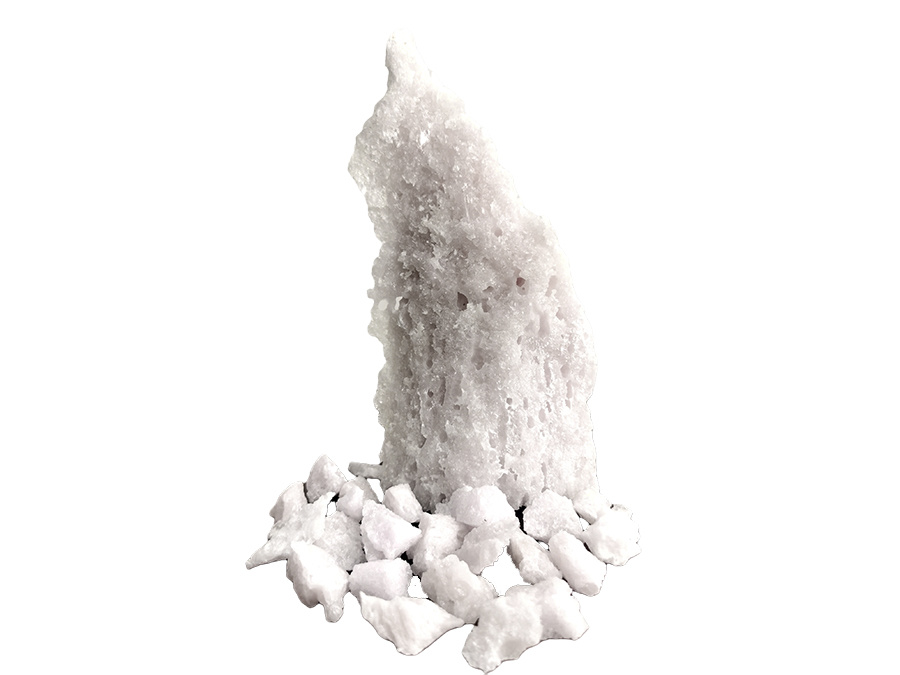

Magnesium aluminum spinel manufacturersTake you to fully understand what is magnesium aluminum spinel. Magnesium aluminate spinel has excellent properties, such as high melting point (2135), high hardness (16GPa), low thermal expansion, high corrosion resistance and excellent optical properties. Widely used in refractory materials, humidity sensors, transparent ceramic materials, anode materials, artificial flange materials and catalytic materials. In the field of refractory materials, magnesia-alumina spinel is mainly used for the preparation of magnesia-alumina spinel bricks, periclase-magnesia-alumina spinel bricks, periclase-carbon bricks and corundum-spinel castables, etc.

Magnesium aluminum spinel manufacturers research shows that additives can promote the formation of magnesium aluminum spinel, promote crystal transformation, reduce the preparation temperature. The additives used in the preparation of magnesium aluminate spinel are mainly rare earth oxides, fluorides, other oxides and composite additives. The addition amount, introduction mode and mechanism of different additives in the synthesis of magnesium are reviewed.

The Role of Oxides in the Synthesis of Magnesium Aluminate Spinel Raw Materials

Rare earth oxides have high melting point, high chemical activity and good corrosion resistance, which have certain influence on the synthesis of magnesium aluminate spinel.

The Role of Fluoride in the Synthesis of Magnesium Aluminate Spinel Raw Materials

Fluoride can promote magnesium to form aluminum spinel. Some experts found that F-doping in the crystal lattice replaced O2-, increased the vacancy concentration and diffusion of cations, and promoted the formation of spinel.Magnesium aluminum spinel manufacturersIt is shown that the addition of LiF decreases the spinel formation temperature and increases the spinel content by forming a liquid phase.

Synthesis Method of Magnesium Aluminate Spinel

Including electric melting, sintering, precipitation, sol-gel, hydrothermal synthesis, combustion synthesis, solution evaporation and supercritical, etc., of which electric melting, sintering is the main method.

1. Sintering method is to mix raw materials such as aluminum hydroxide and sintered alumina with magnesium carbonate, magnesium hydroxide and other magnesium-containing raw materials according to requirements, finely grind together, press into balls (blanks), and calcine at high temperature in a rotary kiln or shaft kiln above 1750 to synthesize magnesium aluminum spinel.

Magnesium aluminum spinel manufacturersThe spinel raw materials synthesized by sintering method contain impurities such as silica, calcium oxide and iron oxide.

2. The synthesis of magnesium aluminum spinel sand by electric fusion method can choose various purity raw materials containing magnesium and aluminum. The content of magnesium oxide in the spinel synthesis raw material is selected between 35% and 50%. Too high or too low MgO content is not conducive to the melting of synthetic sand, because of its high viscosity, the melt is difficult to pour, and the addition of chromium ore is conducive to the melting and pouring of the melt.

Previous Page

RELATED INFORMATION

2024-04-20

2021-05-19

2020-10-11